On-Site Rubber Lining

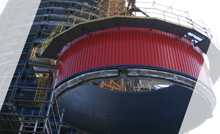

TIP TOP has developed rubber linings for all industrial sectors. The rubber linings can be used on site regardless of the component size. Our on-site rubber linings offer superior protection for storage vessels, pipelines, reaction vessels, flue gas scrubbers, but also for concrete components like septic tanks, deionising and neutralisation basins. REMA TIP TOP on-site rubber linings are not only an excellent choice for the protection against chemical exposure to acids,alkalis, and saline solutions, which become even more potent with increasing temperatures and temperature change, but also against mechanical stress.

WE VALUE THE FOLLOWING PRODUCT PROPERTIES

WE VALUE THE FOLLOWING PRODUCT PROPERTIES

- Permanent chemical resistance and leakproofness

- Permanent thermal resistance

- Permanent mechanical resilience

- Excellent adhesion to the surface (steel, concrete)

- Ageing resistance

- Testability with high voltage

- Crack-bridging capability (concrete surface)

In order to ensure greater durability of TIP TOP on-site rubber linings, the surface requirements must be taken into account. These requirements are regularised in EN 14879-1. The thickness of the on-site rubber lining can be modified with regard to the amount of stress; it is however at least 3 mm. It is possible to use several layers of rubber lining on top of one another.

Different materials are used to accommodate the requirements and possibilities on site.

SELF-VULCANISING RUBBER LININGS

SELF-VULCANISING RUBBER LININGS

... must be stored in a refrigerated place between the time of production and application. These materials are soft rubber linings which are unvulcanised when applied to the substrate and self-vulcanise over an extended period of downtime (several weeks) in ambient temperature of above 25 °C. If necessary, this process can be accelerated by controlled increases in temperature.

PRE-VULCANISED RUBBER LININGS

PRE-VULCANISED RUBBER LININGS

... are single-layered and two-layered sheets of soft rubber which are wrapped onto rolls and vulcanised in autoclaves before application. These rubber sheets can be stored without refrigeration. The rubber lining can be put into operation within two days of application. This interval is required for the chemical reaction of the adhesive.

RUBBER LININGS VULCANISED USING HOT WATER OR STEAM

RUBBER LININGS VULCANISED USING HOT WATER OR STEAM

For the protection of vessels with a capacity of up to 1000 m³, the rubber panels can be vulcanised using hot water or steam. To do so, the container is filled with water following the application of the rubber panels. Within a few hours, the water is heated up to between 95 and 98 °C using steam. If the components are designed to be used under pressure, it is possible to solely use steam vulcanisation. Materials vulcanised with hot water or steam are comparable to autoclave rubber linings with regard to adhesion to the substrate, seam sealing, and chemical resistance. This process is suitable for soft and hard rubber linings and necessary in the case of operation under vacuum conditions.